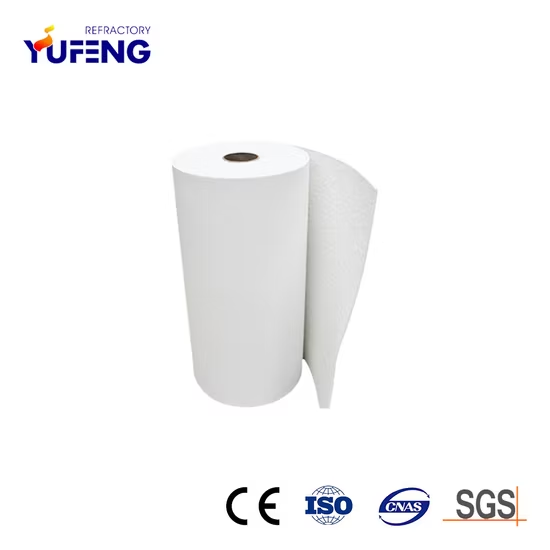

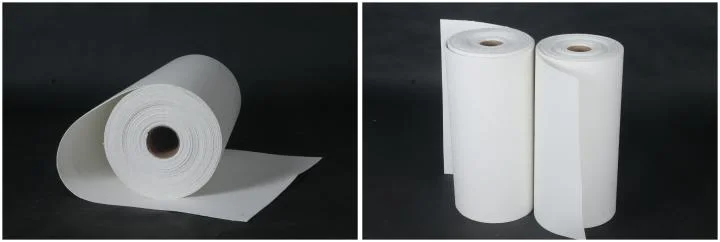

Insulation Ceramic Fiber Paper Packing

Overview Package size per unit product 45.00cm * 45.00cm * 62.00cm Gross weight per unit product 20.000kg Product Descri

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | SJ-PAPER |

| Shape | Ceramic Fiber Paper |

| Manufacturing Technique | Water Wash |

| Kind | High Purity Ceramic Fiber |

| Color | White |

| Thickness | 1-12mm |

| Length | as Your Request |

| Width | 610mm/ 1220mm or OEM |

| Transport Package | One Roll with One Carton |

| Specification | OEM |

| Trademark | SJOIN |

| Origin | China |

| HS Code | 6806101000 |

| Production Capacity | 600000PCS/Year |

Packaging & Delivery

Package size per unit product 45.00cm * 45.00cm * 62.00cm Gross weight per unit product 20.000kgProduct Description

Ceramic Fiber Paper is manufactured by blending high pure alumina silicate fiber, binders, and additives. A specialized paper-making process is used to form uniform, lightweight, flexible paper.By blending different fibers, binders, and additives while varying the manufacturing process, we produce a variety of paper products for a wide range of applications.

Feature & Typical Application

Feature1.Excellent thermal insulating performance

2.Thin, flexible high-temperature insulation

3.Immune to thermal shock

4.Excellent tensile strength

5. Low thermal conductivity

6.Non-wetting to molten aluminium

7.High-temperature stability

8.Easy to wrap, shape, or cut for high-temperature gasket

Typical Applications

1.Used for aerogel substrates in new energy batteries

2.Refractory back-up in various industrial applications

3.Glassware separators and Glass tank refractory back-up

4.Non-Ferrous ingot mould liners

5.Aluminium transfer system backup insulation

6.Parting medium in induction furnaces

7.Automotive heat shields and muffler insulation

8.Insulation of various consumer goods like ovens,stoves, boilers, electric heaters

9.Various molten metal handling applications in steel includes

10. Investment casting mould wrapping

11. Ladle Shroud and nozzle wrapping

12. Ladle back-up

13.Gasket

Data Sheet

| Product Class | STD Paper | BIO Paper | ZrO2 Paper | |

| Classification Temperature(ºC) | 1260 | 1260 | 1430 | |

| Continuous Use Temperature, °C | 1000 | 1000 | 1350 | |

| Colour | White | White | White | |

| Density, kg/m3 | 170-240 | 170-240 | 170-240 | |

| Melting point (minimum),°C | 1760 | 1760 | 1760 | |

| Tensile Strength (MPa) | ≥0.65 | ≥0.65 | ≥0.65 | |

| Loss of Ignition (%) | ≤10 | ≤10 | ≤10 | |

| Shrinkage (24 hours at 1000°C) | ≤3 | ≤3 | ≤2 | |

| Thermal Conductivity (W/m·K) | 0.06(200°C) | 0.06(200°C) | 0.06(200°C) | |

| 0.09(400°C) | 0.09(400°C) | 0.08(400°C) | ||

| 0.13(600°C) | 0.13(600°C) | 0.12(600°C) | ||

| 0.20(800°C) | 0.20(800°C) | 0.15(800°C) | ||

| Chemical Composition (%) | AI2O3 | 42-47 | - | 39-40 |

| SiO2 | 52-57 | 62-68 | 44 | |

| Zr2O | - | - | 15-17 | |

| CaO | - | 20-32 | - | |

| MgO | - | 3-10 | - | |

Workshop

Packaging & Shipping

Exhibiton& Customers

We participate the 6th metal shanghai expo and 15th International Metallurgical Industry Expo. Many our regular customers also came to visit us.

Certifications

Our company has professional and strict quality control for all the products. We have passed CE certificate on 2016.

And we also passed MSDS, ISO9001 quality management system certification and REACH etc.

FAQ

Q1:What is your payments terms?

A1 : 30% T/T in advance, 70% balance to be against the BL copy or by LC, or other payment terms.

Q2 : What is your lead time?

A2 : It usually needs about 10- 20 days after receiving your deposit.

Q3 : How can you control your quality?A3 : For each production processing, SJOIN have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods if needed.

Q4 : Do you provide free samples?

A4 : Yes, free samples are available.

Q5 : Can we visit your company?

A5 : Yes, of course, welcome to SJOIN Company.

Related Products

-

![Good Quality Gland Packings Non Asbestos Gasket Sheet PTFE Graphite Packing with Aramid]()

Good Quality Gland Packings Non Asbestos Gasket Sheet PTFE Graphite Packing with Aramid

-

![Asbestos Fiber Braided Packing with PTFE with Oil Rock Wool Material Braided Gasket]()

Asbestos Fiber Braided Packing with PTFE with Oil Rock Wool Material Braided Gasket

-

![Cotton Fiber Packing with Graphite]()

Cotton Fiber Packing with Graphite

-

![Good Quality Seal Flexible Graphite Gasket Carbonize Fiber PTFE Packing Graphite Fiber Packing]()

Good Quality Seal Flexible Graphite Gasket Carbonize Fiber PTFE Packing Graphite Fiber Packing